WELCOME TO NANOFAB.SDSU

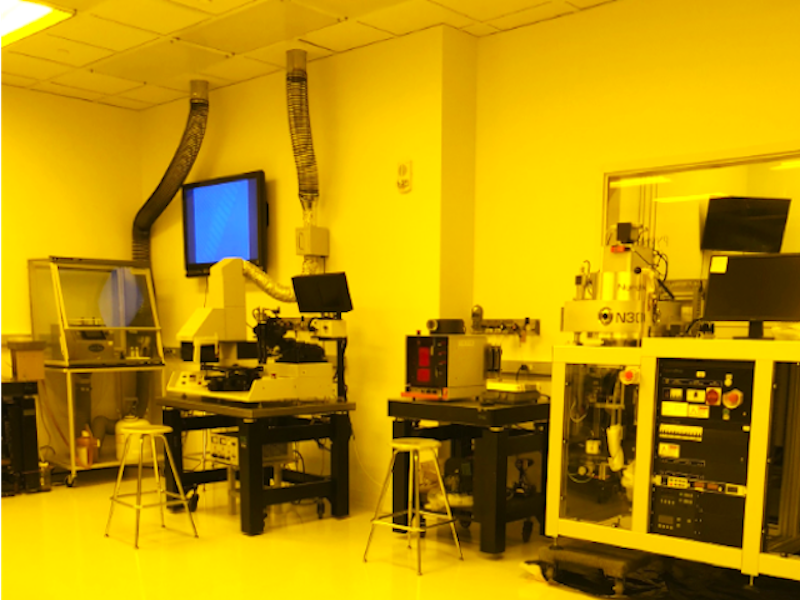

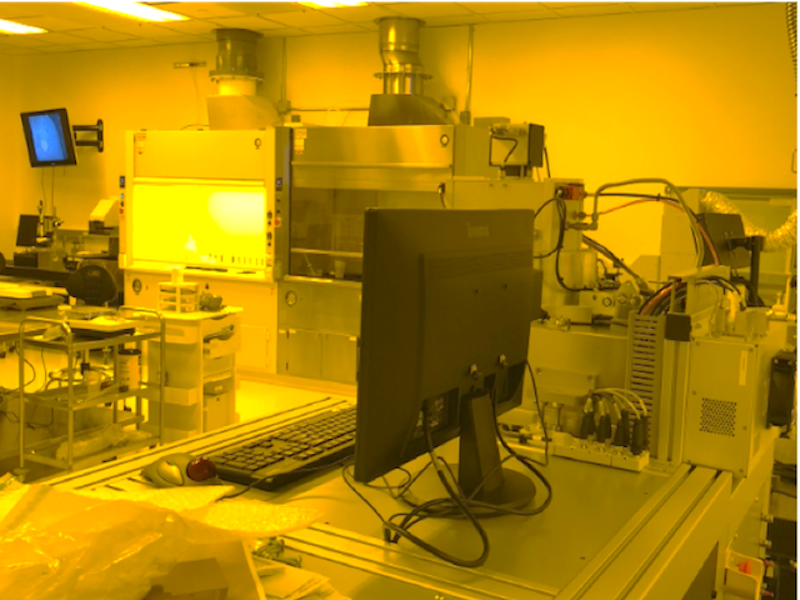

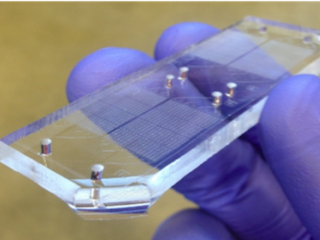

Welcome to NanoFab.SDSU, a brand-new leading center for micro and nanofabrication located in the EIS building of SDSU. The state-of-the-art facility has a 2500 sq. ft. ISO 9001-certified Class 1000 Cleanroom with 4” and 6” wafer processing capability with 0.2 micron lithography feature sizes. The Center provides a comprehensive and expanding selection of state-of-the-art process equipment for lithography, etching, thermal processing, thin-film deposition, and characterization. The vision of the Center is to become a leading national and international center of integrated silicon and polymer/carbon-based micro and nanofabrication facility to support user needs in newer areas of nanoscale science, engineering, and technology domains. The Center has a strong focus on educating undergraduate, masters and doctoral students in the various areas of nanotechnology.

Equipment & Facilities

- ABM, High Resolution Mask Alignment and Exposure System (0.2 micron resolution)

- PECVD & Pyrolysis Split-Tube Furnace with Vacuum

- Nordiko Metal Deposition System. Co-deposition of up to 4 metals.

- Technics Series 85 DRIE and Plasma Etcher

- OAI UV Light Source

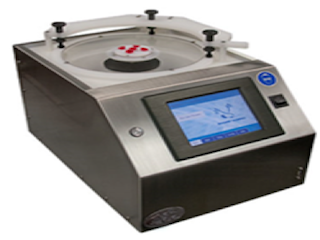

- Brewer Spin-coater

- ETS-150 Thermal Evaporation + Sputtering

- High-temperature ovens

- Signatone Probe Station and 4-Point Probe

- Filmetrics F40-PAR Profilometer

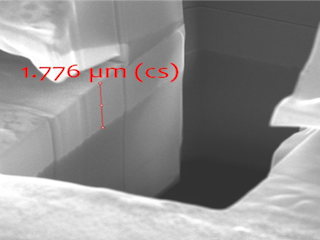

- Hirox 3D Microscope

- Newport Solar Simulator with Oriel I-V Station

Management

Director of Center

Professor Sam Kassegne

kassegne@sdsu.edu

Capabilities

- CVD/PECVD for Dielectric Materials

- DRIE

- Wet and Dry Oxide Growth

- Thin-film Metal Deposition (Au, Pt, Cr, Ti, Ni, Cu)

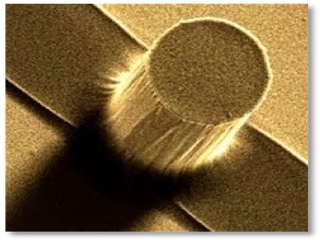

- Graphene, Glassy Carbon, CNT

- Acid (Wet) Etching

- Pyrolysis

- SEM and 3D Microscopy

SERVICES

Major Achievements

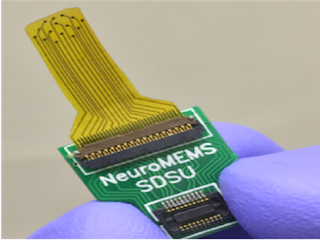

- Several patents and disclosures in MEMS IMU, organic solar cells, neural probes, and graphene processes.

- Incubated start-ups and licensed variety of technology

- Unique strength in integrating carbon, polymer, and silicon-based microfabrication.

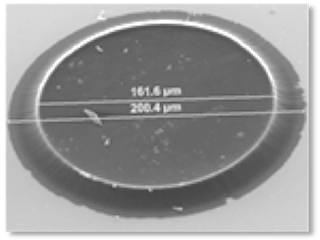

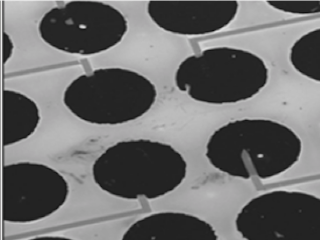

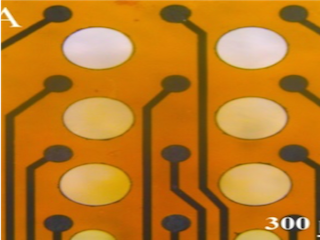

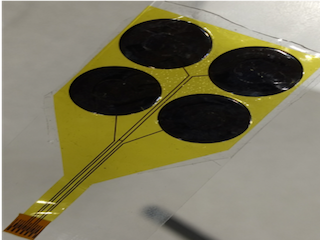

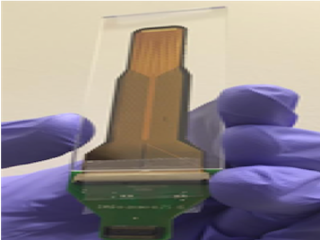

- First to introduce single and double-sided pattern transfer technology for carbon microelectrodes on polymer substrates

- Hosted CMEMS 2018 Conference.

- Training next generation of workforce and researchers (alumni work in Apple, Intel, Qualcomm, ASML and several start-ups).

- Funded by NSF, DoE, DoD and Industry

Offering Services To:

Industry

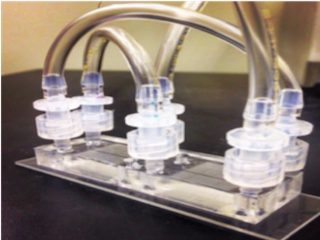

- TumorGen MDx (microfluidics chips)

- TissueNetix (microfluidics chips)

- Grapheton

Research Labs

- University of Washington (CSNE) – (cortical and spinal neural probes)

- University of Texas at Dallas

- Physikalisch-Technische Bundesanstalt (PTB) Braunschweig, Berlin, Germany

- University of Ferrara – (ECoG Neural Probes, 12, 32, and 64-channels)

- University of Indonesia

- Yonezawa University (Japan)

- SPAWAR, SSC-Pacific, US Navy

MEMBERSHIP

Advantages of Membership

- Direct access to highly-trained students

- Interaction with leading researchers

- State-of-the-art equipment and processes

- Participate in annual Industry Day�

- Reduced rate for members

- Simple paperwork

- No institutional barriers

- Your IP is protected

- Opportunity to license IP from consortium labs.

PORTFOLIO

CONTACT

- Sam Kassegne, PhD, PE

Professor of Mechanical Engineering,

Deputy Director, NSF Center for Sensorimotor Neural Engineering

Department of Mechanical Engineering

San Diego State University

5500 Campanile Drive, EIS - 214

San Diego, CA 92182, USA

kassegne at sdsu dot edu